If you learned anything as a kid, it was to say “NO” to crack. It’s time we all took another look at those life-guiding words of wisdom. Because welding cracks are a common, yet incredibly serious issue. In fact, a crack can completely ruin the integrity of a weld, rendering it useless. For this reason, some industries go to incredible efforts to test and examine welds for any sort of cracking. Why does cracking happen and what can you do to fix it or prevent it from happening altogether?

Why does cracking happen?

Cracking can be caused by many different problems from rapid cooling to contamination. But in almost all cases, the reason cracking occurs is because the internal stresses exceed either your weld, your base metal or both. After you weld, both your base metal and your weld begin shirking as they cool. This creates internal stresses. If in some way you’ve compromised the strength of your weld or base metal so it’s weaker than the stresses, it won’t be able to hold itself together and begins cracking.

Common crack causes

Often cracking is grouped into different types, of which we’ll cover 3 of the most common. Hot cracking accords with temperatures above 1000 F. The nice part about hot cracking is that because of the extreme temperatures, the cracks tend to happen more immediately, meaning you’ll often know when you screwed up (though not always as the crack may occur somewhere not visible to you such as with the base metal).

The first common cause for hot cracking is material type or contamination. Certain materials such as free machining steels are known to have issues with cracking. Also, any sort of paint, rust, dirt or protective material such as zinc (often used to galvanize surfaces) that gets caught in your weld pool will decrease the strength of the weld making it susceptible to cracking.

The other common cause for hot cracking is when the bead is too wide with a thin throat. By spreading your weld too wide and thin, there’s not enough strength to overcome the stresses of shrinking.

Cold welding cracks are more likely to appear either days or weeks after the weld is complete. Cold cracking often happens when hydrogen gathers around imperfections in the weld, causing increased pressure on the structure of the weld. This overall process of hydrogen diffusion takes time, leading to delayed cracking.

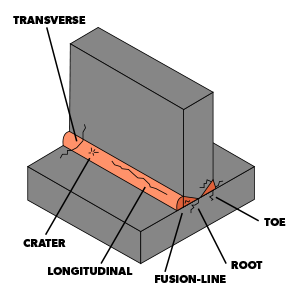

The other common type is known as a crater crack. This happens when a crater is not filled completely before the arc is broken. The outer edges cool faster than the center of the crater, causing internal stresses that can result in a variety of different crack types.

Preventing and Fixing Cracks

Cracks are common while experimenting with new processes, base metals, filler materials, etc. Because of this, cracks are just going to happen as you gain experience. Fixing cracks entirely depends on your project. For many cracks, you might be able to gouge out the crack and repair the weld. However, certain welds that must be done according to code might not allow for this type of luxury. In these cases, the whole weld or even workpiece will need to be redone.

Because of this, prevention is always preferred. Carefully choosing base and filler materials is a good first step. Also, correctly storing your filler material can significantly help. Cracks caused by spreading the bead too thin can be remedied by using enough filler and making sure your pieces fit together correctly.

Besides base and filler materials, often adjusting your travel speed and voltage settings will allow enough filler material to withstand the internal stresses as the metal shrinks. As mentioned, contaminates can also reduce the strength of your weld, so make sure your workpiece is adequately cleaned for the process you’re using. In some cases, preheating might be necessary.

Cracking can be caused by any one of a thousand issues. But understanding why cracks occur and knowing some of the common causes and prevention methods will help you on your path to a crack-free life.

Another common issue most welders face is burnback. Check out one of our most-read post on avoiding burnback by clicking the button below.