Up until a few years ago, only mass-manufactured products tended to be planned out beyond a simple sketch and some rough dimension estimations. Recently, there's been a huge influx in easy-to-use, free options for planning out your projects. This can mean huge cost-and-time saving benefits, especially if math isn’t your strong suit.

Here’s an in-depth rundown of the most common ways to plan out your project, looking at the pros and cons of each to give you multiple options to choose which works best for you and your project.

Option 1: Wing It

It’d be easy to simply say the worst plan is no plan at all. But the truth is, it might be the perfect option in certain situations. When winging it, you’ve got very little idea what exactly comes next. Each step simply builds on top of the other, although hopefully you’ve got a general idea of where your project needs to end up.

The downside to winging it is that you’re almost completely depending on your experience and skill. If you’re unfamiliar with what you’re building, there’s a strong possibility you’re going to run into some issues that you didn’t even think about.

For example, you want to build a workbench, so you start with the drawers. You get those all welded up only to realize that the overall size of your workbench is now going to be too big.

The benefit of winging it is that you have to put absolutely zero hours into the planning stage, allowing you to get to the real work immediately. If you’re a skilled welder familiar with the project you’re creating, this can actually be the most efficient option.

Option 2: Sketch It Out on Paper

This has traditionally been the most common option, simply based on how accessible it is. All you need is a piece of paper, a pencil, a measuring tape and a calculator.

By sketching your project out, you can develop a step-by-step plan. This gives you a way to visualize issues you might run into and figure out your dimensions before you begin.

The downside of pen and paper is that you have to rely on your drawing and math skills to keep your plans accurate. The more complex your project gets, the more difficult this becomes. Unlike a CAD program that gives you visual feedback, if you do your math wrong, you might not realize it until halfway through your project.

Option 3: CAD Software

15 years ago, only engineers really had CAD programs as an option. Heck, just understanding how to use the programs basically took a degree. But recently, more and more options are becoming available that are free and incredibly easy to use.

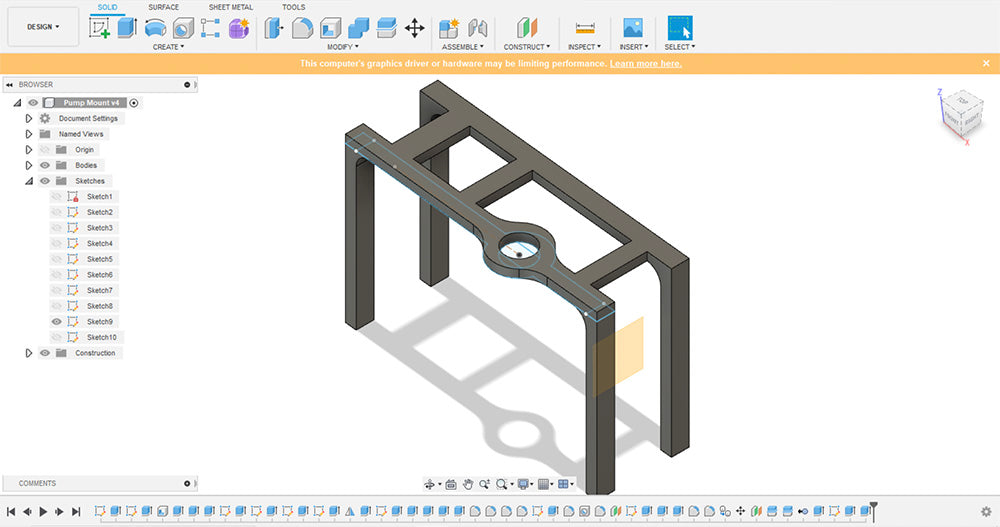

The major benefit of CAD software is that it’s like sketching your project on paper, but almost all the math is done by the program. You also get visual feedback. For instance, if you’re building a table and make the top too short, you’ll see it in the rendered design. This allows you to fiddle around and try new things without actually wasting material.

For the actual software, Fusion 360 is robust and yet still incredibly easy to use. As long as you’re using it for hobby purposes, it’s free (just make sure you get the “personal version” which you can find here).

A lot of welders also prefer SketchUp which has a similar pricing structure, being free for personal use. There’s also TurboCAD or DesignCAD, though these do have a higher price point. For all of these programs, there’s an infinite source of tutorial videos on YouTube that do an excellent job of teaching you everything you’ll need to know.

The only downside with these CAD programs is that a computer is often required. If you’ve ditched the desktop and only have access to a smartphone, there’s still a number of apps available. While it lacks some of the features of the programs mentioned above, Draft Paper is great for sketching out your designs. AutoCAD is similar except that it’ll also measure your dimensions, a great tool for anyone who doesn’t particularly love math.

No matter how much planning you do, a few things will fudge up even the best designs, such as warpage and using poor consumables. Having the right clamps can help prevent warpage and keep your material aligned correctly. We recommend Strong Hand clamps. For consumables, you won’t find better quality and selection than at Welding Supplies from IOC.