If welding had unlockable achievements, porosity would be on everyone’s list. It’s just part of the welding learning curve. In fact, it’s not uncommon to see welders with years of experience whose beads still look like an ant hive. But does porosity really affect your weld, and if so, what can you do about it?

Is Porosity Really That Bad?

Especially among stick welders, you’ll see a lot of welds riddled with holes (though it’s also common with MIG and TIG welds too). Now you might hear, “It looks horrible now, but once it’s cleaned up, it’ll look great.” Is porosity really just an issue for those welders trying to post their beads on Instagram, or does it actually affect the integrity of your weld?

Unfortunately, porosity is more than just a visual defect. In fact, porosity is one of the first signs to let you know that your weld is probably compromised. Generally, porosity results in a weaker bond, meaning your weld might not hold up too well in both the short and long term. For anything that’s structural, porosity should be an instant sign your weld needs to be re-done.

So yes, porosity is basically the equivalent of having a hundred squirrels trapped in your pants: It’s bad. And how do you deal with squirrels in your pants? Well, you really don’t. At that point, you really just have to hope they’re not the kind of rodents that bury nuts. The secret with both squirrels and porosity is to avoid the situation completely in the first place.

What Causes Porosity?

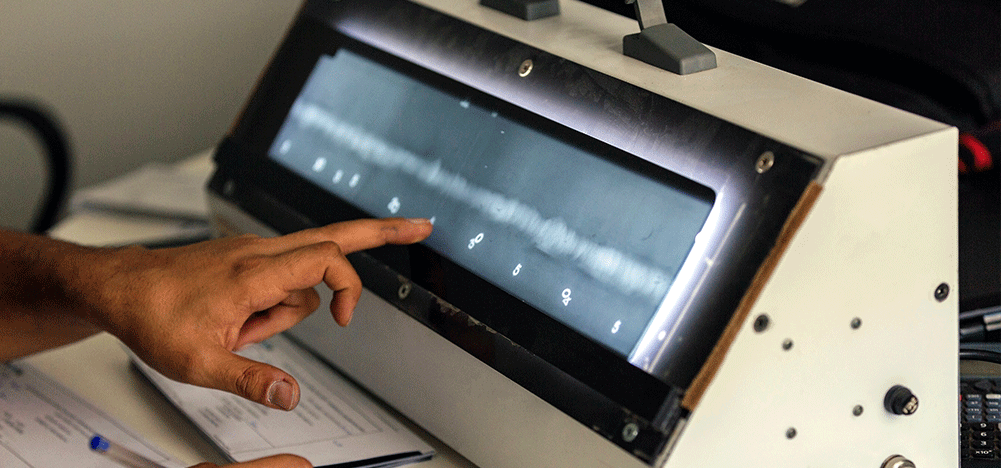

Let’s take it down to the most fundamental level. The holes and tunnels from porosity are caused by gases getting trapped in your weld pool. This prevents the molten filler material from “filling” those spaces, leaving empty pits in your weld.

While all porosity is more or less caused by these gases getting trapped, how they get there is the difficult-to-answer question. We’ll take you through the most-common to least-common potential solutions.

Contamination

In many ways, your welding pool is like making a soup. Anything that gets added will affect the final product. This means if any kind of dirt, grime, rust or paint gets left in your weld pool, it’ll impact the end result. The good news is that this is an easy issue to fix.

If you’re seeing porosity in your beads, first make sure that you’re thoroughly cleaning the area around where you’ll be welding. Some paints claim that they’re designed to be welded through without needing to be removed. However, if you’re seeing porosity trying to weld through paint, it’s best just to remove it first.

Moisture can also contaminate your weld. This can be especially difficult if you’re trying to weld in very humid conditions or outside during the winter.

Shielding Gas Problems

The purpose of shielding gas is to flood the area around your weld pool with gases that won’t react to your weld. Basically, this pushes away the atmosphere, which would normally react with the metal and cause all sorts of problems. A common misconception is that stick doesn’t use shielding gases. In reality, the shielding gases are actually baked right into your stick electrode and released as the rod melts.

When shielding gases are improperly applied or not enough is used, it allows the atmosphere to come in and cause all sorts of problems with your weld (including porosity). However, sometimes welders know this and will overdo it. They turn their protective gas flow up to eleven, thinking this guarantees that their pool will be protected. This can actually cause the gases to push out too forcefully, creating more dramatic highs and lows in pressure around the weld pool. The air can actually get sucked in around the weld pool, meaning that turning your shielding gas up too high can actually cause the very thing you’re trying to prevent.

Bad Equipment

Sometimes welders will try every possible solution to stop porosity with no luck. In reality, the problem might not be anything you’re doing. Defective or poorly-manufactured welding products can have all sorts of problems that cause porosity. For instance, shielding gas can become blocked or inconsistently released, allowing atmosphere to come in and contaminate the pool.

Cracked o-rings and MIG liners are also common problems. When damaged, these allow the atmosphere to seep into the shielding gas before it even reaches the weld, so you’re literally protecting your pool with an already contaminated gas.

Another common issue is that your nozzle can become blocked with spatter, disrupting the shielding gas coverage. If you’re using old or poorly made equipment, don’t forget to check Welding Supplies from IOC for new machines. With our loyalty program (which is free to join), you’ll get the best prices on the internet.

Bad Mixture

While not that common, there is a possibility that the problem causing porosity is your shielding gas itself. Defective cylinder fittings can allow air to slip into your mixture. Another possibility is that the gases in the cylinder were accidentally contaminated with impurities by your supplier. This is why having a trusted gas supplier can go a long way when achieving high-quality welds.

If you suspect your gas in the cylinder is contaminated, try switching out the cylinder for a different one (if possible). If the problem disappears, you might want to think about finding a new supplier. Often the biggest gas supplier is not necessarily the best, so read reviews and check with other welders on who they trust, if you’re looking to make a switch.

With these steps, you can eliminate most of the major causes of porosity and really increase the quality of your welds. For more tips, tricks and guides to improving your skills, check out our complete blog here.