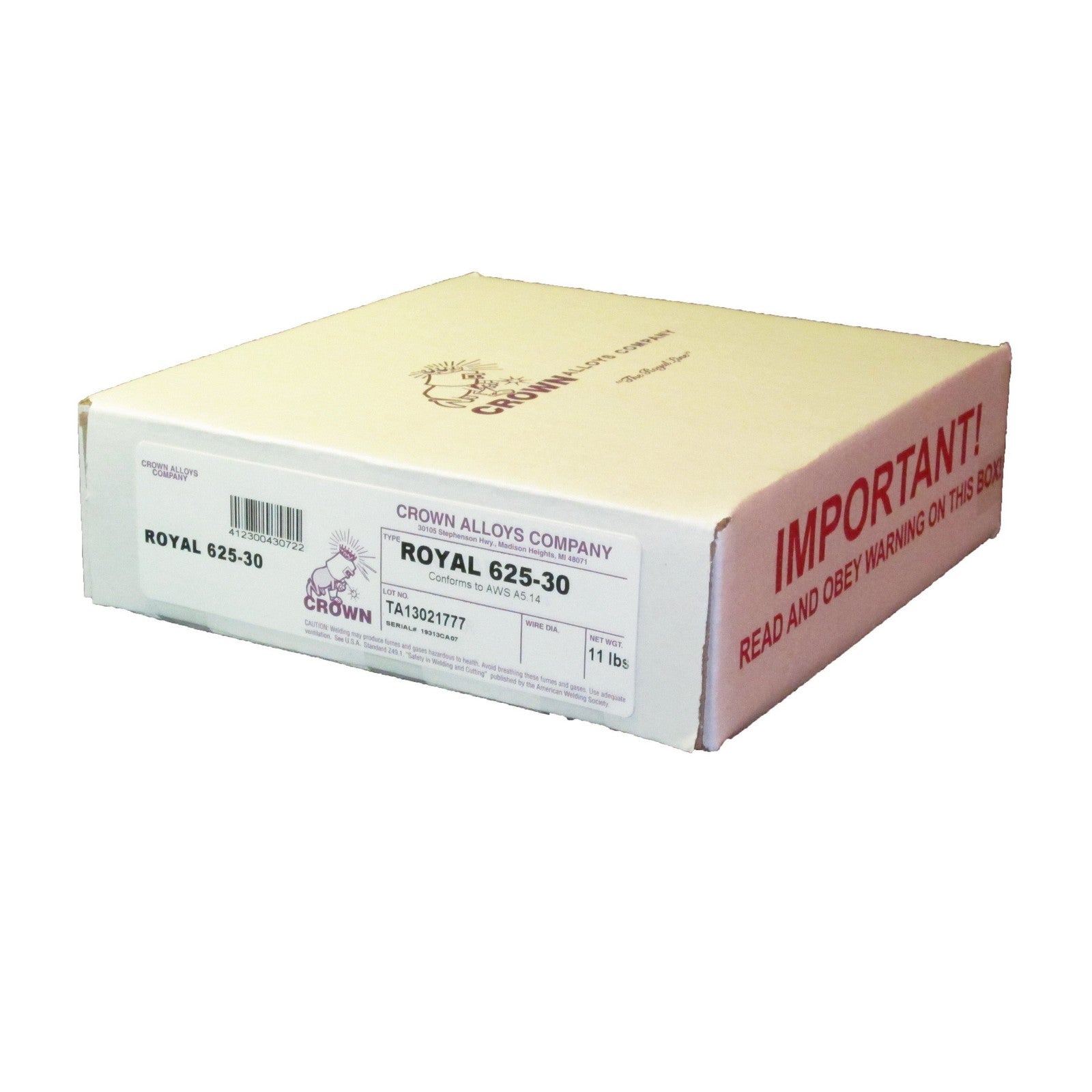

Crown Alloy .035 x 8" ROYAL 625-30 Iron-Nickel-Chrome (ER NiCrMo-3) MIG 11 lb SPOOL (RS625/2F)

Royal 625-10 (TIG) and Royal 625-30 (MIG) provide high strength welds over a broad temperature range and have exceptional corrosion resistance, including resistance to localized attack such as pitting and crevice corrosion. The aforementioned characteristics make this an ideal alloy for surfacing or cladding of steel as well as joining. This alloy is used extensively in chemical and food processing equipment, aerospace and marine engineering, pollution control equipment such as scrubbers, petroleum refining equipment and petro-chemical equipment. Royal 625-10 and Royal 625-30 are used to join Inconel alloys 625, 601, and 690, and Incoloy alloys 800HT, 800, and 825. Also used to weld 9% nickel steel and Inco alloy G & G-3. It will also join alloys 317LM, 254SMO, AL-6XN, 20 Mo-6, 904L and heat & corrosion resisting castings like HK40, HT and HY. Royal 625-10 and Royal 625-30 are useful for many dissimilar joints involving Inconel and Incoloy alloys, carbon steels, low-alloy steels and stainless steels.

Please Note: Welding fumes and gases can be hazardous to your health. Click here for the manufacturers MSDS information. Both the manufacturer and Welding Supplies from IOC recommends that you read and understand the Material Safety Data Sheets and product warning statements prior to using this product.

Please Note: Welding fumes and gases can be hazardous to your health. Click here for the manufacturers MSDS information. Both the manufacturer and Welding Supplies from IOC recommends that you read and understand the Material Safety Data Sheets and product warning statements prior to using this product.

| MPN: | RS625/2F |

|---|---|

| UPC: | 412300430722 |

MPN: RS625/2F

UPC: 412300430722

Brands you trust at prices you can afford!

Over the past decade, we've become the country's most trusted one-stop online welding shop. We've done it with the guaranteed lowest prices, the best customer service in the industry, and a commitment to providing the best online shopping experience for all welders.

------------------------------

From The Blog

MIG

Lincoln’s NEW Power MIG 220: the Ultimate All-in-One Machine

For TIG welders, most multiprocess machines have always had a critical flaw: They cannot TIG weld aluminum. When working with that type of material, AC TIG must be used in almost all cases. But for...

TIG

Syncrowave 212: Is It a Worthy Successor to Miller’s Beloved TIG welder?

TIG welding is like patting your head while rubbing your belly, while also doing a Rubik's cube with your feet and whistling Yankee Doodle. Simply put, you’ve got a lot going on while TIG welding (...

Helmets

Is the Miller T94i-R PAPR System Worth It?

Let’s drop a hard truth: In the welding world, an experienced welder is worth more than 20 beginner welders. This is often directly reflected in the pay for welders. Some highly skilled welders can...