You peer over the edge of a muddy trench as bullets whiz overhead. Blurry black shapes struggle towards you through the rain and slurry. A man behind you runs down the trench, screaming in a thrill voice, “Here they come!” And then the shelling starts. Explosions that rock the earth around you. Power so terrifying, nothing in the history of the world could compare with this moment. As the bombs rain down, you notice that the explosive shrapnel doesn’t just embed itself into other metals, it’s actually welded together at the spot of impact.

This was, in fact, how explosion welding was first discovered. As the beginning of WWI ushered in the use of high-powered artillery, soldiers began noticing that metal plates struck by enemy shells would actually contain welded pieces of shrapnel. The phenomenon would occur even if the 2 pieces were dissimilar metals.

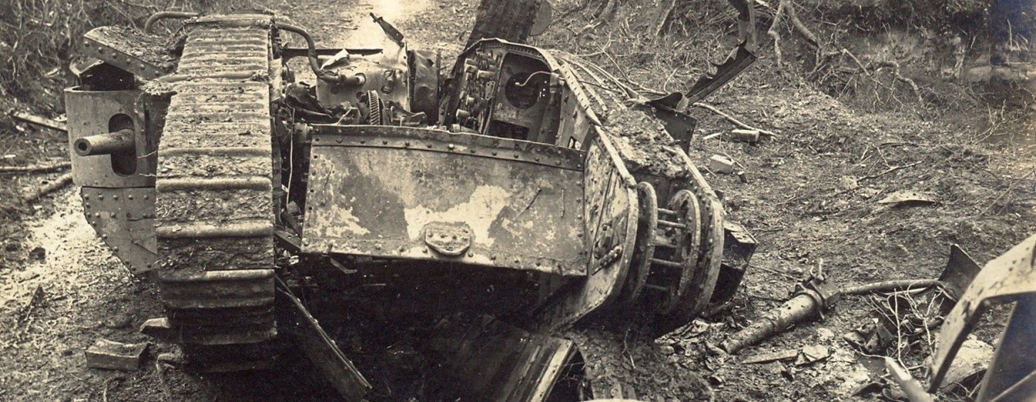

Soldiers first noticed explosive welding when artillery struck the metal plates of objects such as tanks.

It wasn’t until over 40 years later that the Du Point Company successfully patented the process of explosion welding. In theory, the procedure is fairly easy to explain. Using an explosion, one piece of metal is accelerated at high velocity towards another. Their impact results in a solid state bond between the pieces, successfully welding them together.

So why don’t we use rocket launchers instead of welding machines? While properly placed explosions might weld metal, they’ll literally blow up anything else within the area. This means explosion welding is best suited for only certain types of situations. Generally, it’s used to create clad plates. These normally consists of a thicker piece of steel and a thin layer of corrosive resistant metal (for instance, stainless steel, nickel alloy, etc.). The 2 pieces are placed atop one another and then covered with a high-powered explosive. Once detonated, a series of well-timed explosions push on the top plate with over 2 million psi. This causes it to accelerate downward towards the bottom plate at incredibly high speeds. The impact fuses the 2 pieces together in a way you couldn’t do with a traditional welding machine.

The real benefit of explosion welding is that it can be used to combine highly dissimilar metals in ways very few processes can. In fact, over 260 different metal combinations are possible. The actual weld is also created incredibly quickly, although the preparation before the explosion takes an extensive amount of time.

So besides the massive amount of collateral damage that it would cause, why isn’t explosive welding used more often? Because explosives don’t work well with complex shapes, explosion welding is limited to simple applications such as flat plates or basic cylinder structures like tubes. For the most part, the clad plates that explosion welding produces are used in heavy-duty industrial settings.

If you’re interested in other bizarre and exciting ways welding happens beyond the normal MIG, TIG and stick processes, check out our post on Welding Processes You’ve Never Heard Of. To finish off, here’s actual footage of an explosion weld being performed.