Power requirements have never been demonstrated better than 1989’s Christmas Vacation. As Clark Griswald excitedly goes to plug in his elaborate Christmas lights display, his joy turns to dread as he realizes that he’s vastly miscalculated his power situation. While this indirectly leads to a Santa decoration being launched thousands of feet in the air, the basic concept of this situation is not too far from the same experiences that many welders have.

In this article, we’ll explain welding power sources and how to properly understand and calculate your welding electrical power needs. We'll also cover how they compare to your home or workshop’s setup.

Using a 120-Volt Plug

When it comes to powering heavy-duty equipment like welders and plasma cutters, understanding the voltage requirements is crucial. Many machines, such as the Lincoln Square Wave TIG 200, offer flexibility in voltage inputs: it can be plugged into either a standard 120v socket or a more robust 240v socket --- there is no such thing as a welding outlet. However, it's important to note that the machine's performance varies significantly depending on the voltage of the welding power supply.

For instance, when plugged into a 120-volt outlet, the Square Wave TIG 200 can output up to 125 amps. Despite its name suggesting capabilities up to 200 amps, achieving this requires a 240-volt connection. Household 120-volt sockets, ubiquitous for everyday appliances like cell phone chargers and toasters, are convenient but cannot supply the higher power demands of welding equipment. So, while you can plug a welder into a regular outlet, it might not be enough to power a 240v welding machine.

Using a 240-Volt Plug

While it's possible to put a 240v welder power plug into a standard 120v outlet, you won't get the sufficient welding voltage required by the machine to operate properly. That's because the output power of a welder depends on the input power. To harness the full potential of a welder at 240V, such as the Lincoln Square Wave TIG 200, a dedicated 240-volt plug is necessary. These plugs, similar to those used for ovens and dryers, are typically installed in specialized settings such as welding workshops or modified garage spaces.

Switching to a 240-volt plug allows the Square Wave TIG 200 to reach its peak capability of 200 amps. These outlets are designed to handle higher amperage demands, ensuring efficient operation of heavy-duty welding equipment.

Single-Phase Power vs. 3-Phase Power

Most consumer-grade welding equipment operates on a single-phase power supply, available through standard 120-volt or 240-volt outlets. However, industrial-grade machinery often requires a 3-phase power supply to effectively meet higher power demands.

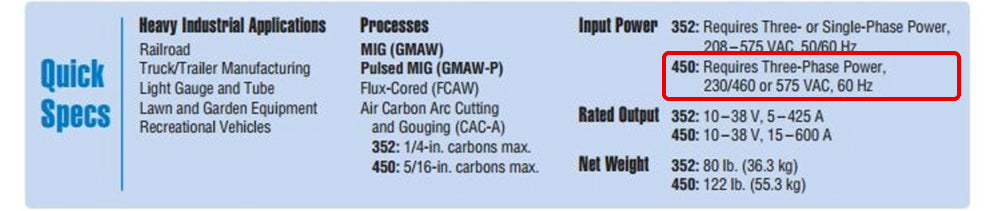

Three-phase power outlets, identifiable by their four slots, can deliver three times more power than single-phase outlets. This significant increase in capacity is crucial for industrial applications where heavy-duty machines like the Miller Invision MPA MIG welding machine are used.

For example, the Miller Invision MPA 352 version can operate on either single-phase or three-phase outlets, though performance may be limited on a single-phase supply. Conversely, the 450 version of this machine strictly requires a 3-phase outlet for operation, highlighting the necessity of checking power supply compatibility before investing in industrial-grade welding equipment.

Plasma Machines

Many plasma machines require a 240-volt socket and will not work at all with 120 volts. For instance, the Hypertherm Powermax45 XP requires a 240-volt socket that’s able to draw up to 39 amps. Before you purchase a plasma welder, make sure you check the power requirements.

Who Needs a Power Grid?

For some welders, plugging into a workshop or garage power grid isn’t an option. This is when a generator or welder/generator comes into play. Most of Lincoln and Miller’s welder generators come with at least one 240-volt socket. This allows you to not only use the welder built right into the generator, but you can also run a plasma machine off the same generator—or even run a separate 240-volt welding machine.

Especially for welders who work in the field, an engine-driven welder or a generator might be the only way to meet your power needs. Just make sure you check the specs before you buy. You’ll want to be sure it has the right type of plugs you need and can handle the number of amps you require. For more information about calculating generator power requirements, check out our in-depth article here.

Welding Generators and More at Welding Supplies From IOC

When you purchase at Welding Supplies from IOC, our experts are always able to answer any questions you have about power requirements or machine specs. That’s something you’ll never find at a lot of these online stores. It’s part of our commitment to having the best customer service in the industry. We also offer the best prices and brands. Check out our complete line of equipment and gear here.