“Life on the farm”. For some people, the phrase conjures up images of straw-hatted hillbillies pulling potatoes out of the ground with their bare hands. In reality, modern farms in the US are actually some of the most technologically advanced places on the planet. Few farms rely on human laborers anymore. Instead, a huge host of machines form the backbone of American agriculture. And with these machines comes a lot of metal. Metal that often has to be repaired by welding. This means a huge portion of the welding community is made up of welders who work part-time or full-time on farms.

Also, because of the diverse variety of repair and fabrication jobs required on a farm, the need for human welders makes this one of the last places where a robot welder will be replacing flesh and blood.

The sheer amount of welding work and human ingenuity that farm jobs require makes knowing the right way to farm weld an invaluable skill (even if you don’t actually live on a farm). To help you do farm welding the right way, here are a list of questions you should ask yourself before starting any new project:

Where do you need to make the repair?

Are you welding something you can drag back to your workshop, or are you making a house call to that baler stuck in a field? Answering this question will help you determine how portable your equipment needs to be. Even if a repair has to be made on a roof, a small Stick welder can still operate on a really long extension cord. If you have a welder/generator like a Bobcat or a Ranger, they’re perfect for remote fieldwork.

What metal type and thickness are you welding?

Certain machines should only be used on certain metals, and there’s plenty of different metals on a farm. Stick can generally only weld steel and stainless steel, while MIG can also do aluminum. TIG can do all weldable metals. Stick can weld 1/8” and up, MIG can weld 24 gauge and up, and TIG can weld as small as 22 gauge and up. Make sure you use a machine that can handle the thickness and type of material you’re using.

How fast do you need the repair and how strong should it be?

There’s always something on a farm that needs to be hard-surfaced or repaired. That means you’ll need to balance the quality of a job vs. how much time you have. Be aware that TIG welding is very slow and difficult to master, but makes a high quality weld. Stick is not as slow (medium difficulty), and MIG is very fast (easy to learn and decent quality). You may not have time to do a masterpiece weld on that gate, or else the cows will never come home. On the other hand, you may decide you need to invest the time in a really solid weld on that silo so the harvested crops aren’t damaged. Make sure you know before you start what quality is expected and how much time you want to commit. These 2 things can drastically affect the equipment you decide to use.

What’s the cost of the weld?

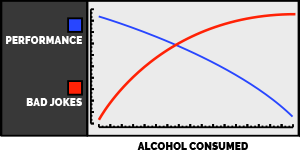

Often new welders like to use Stick machines because the initial cost of the unit is lower. However, most MIG machines actually have the lowest operating cost. If you’re skilled in all 3 processes, what equipment you use will probably be based on the previous 3 questions.

However, in some situations, 2 or even all 3 processes might work. In this case, it’s important to weigh the cost vs. quality. MIG welding a damaged corral fence might cost less than TIG, but might not be at the same quality.

The same can be said for the type of fillers and consumables you’re planning on using. A premium quality (more expensive) electrode might not matter too much in one job and mean everything in another.

In every case though, you’re going to want to make sure you’re getting the best price on all your equipment. Sure, you could go to some big box store. But the cost of that physical location literally goes into the prices of things you buy there. That’s why Welding Supplies from IOC decided to go online. We take the money a store would cost us and pass those savings on to you. Plus you can literally get everything you need at home in your underwear. Now that level of freedom brings a tear to our eyes.

See for yourself why IOC is the best place to get your consumables, equipment and safety gear.