Arcair K4000 Heavy-Duty Carbon Arc Gouging Torch (61082009)

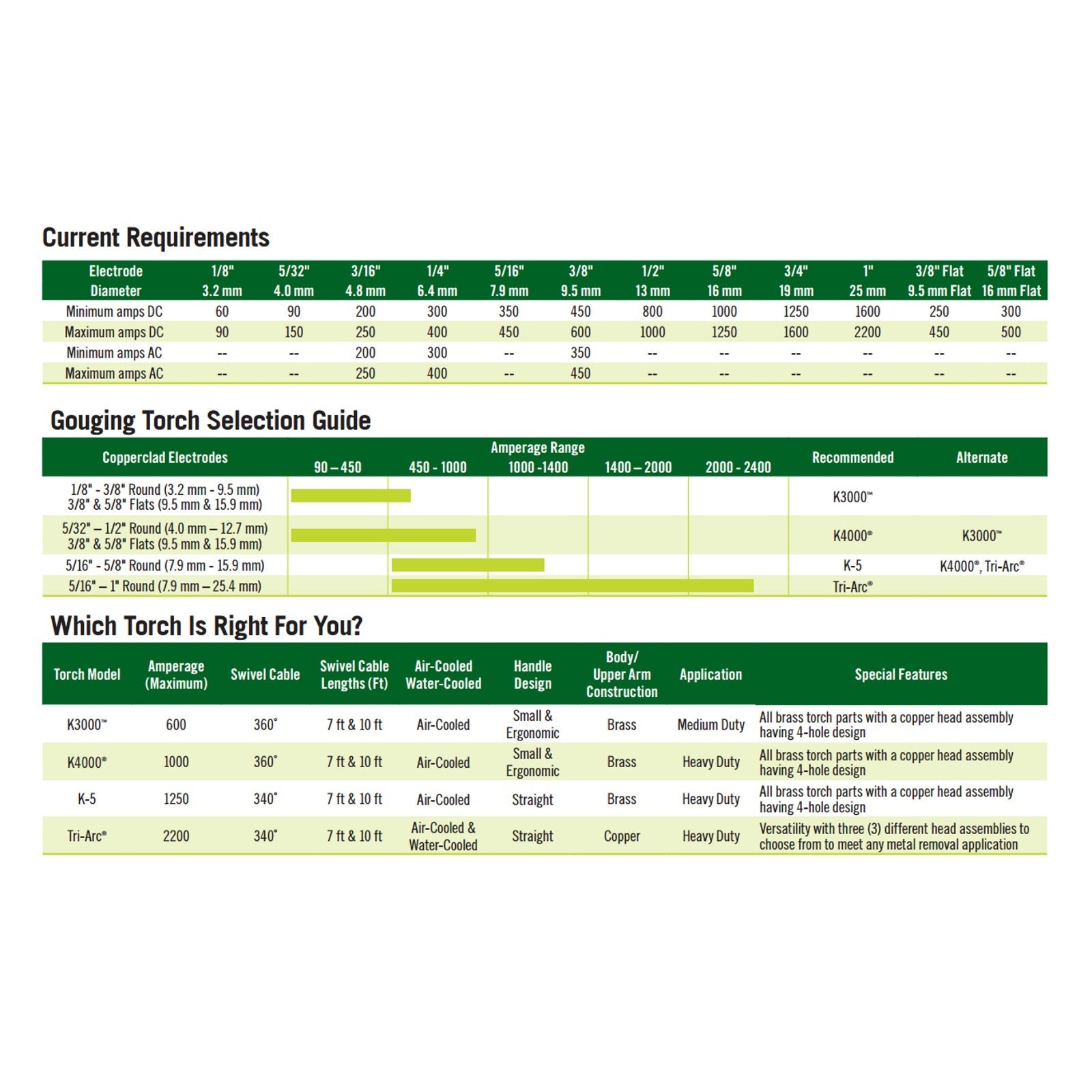

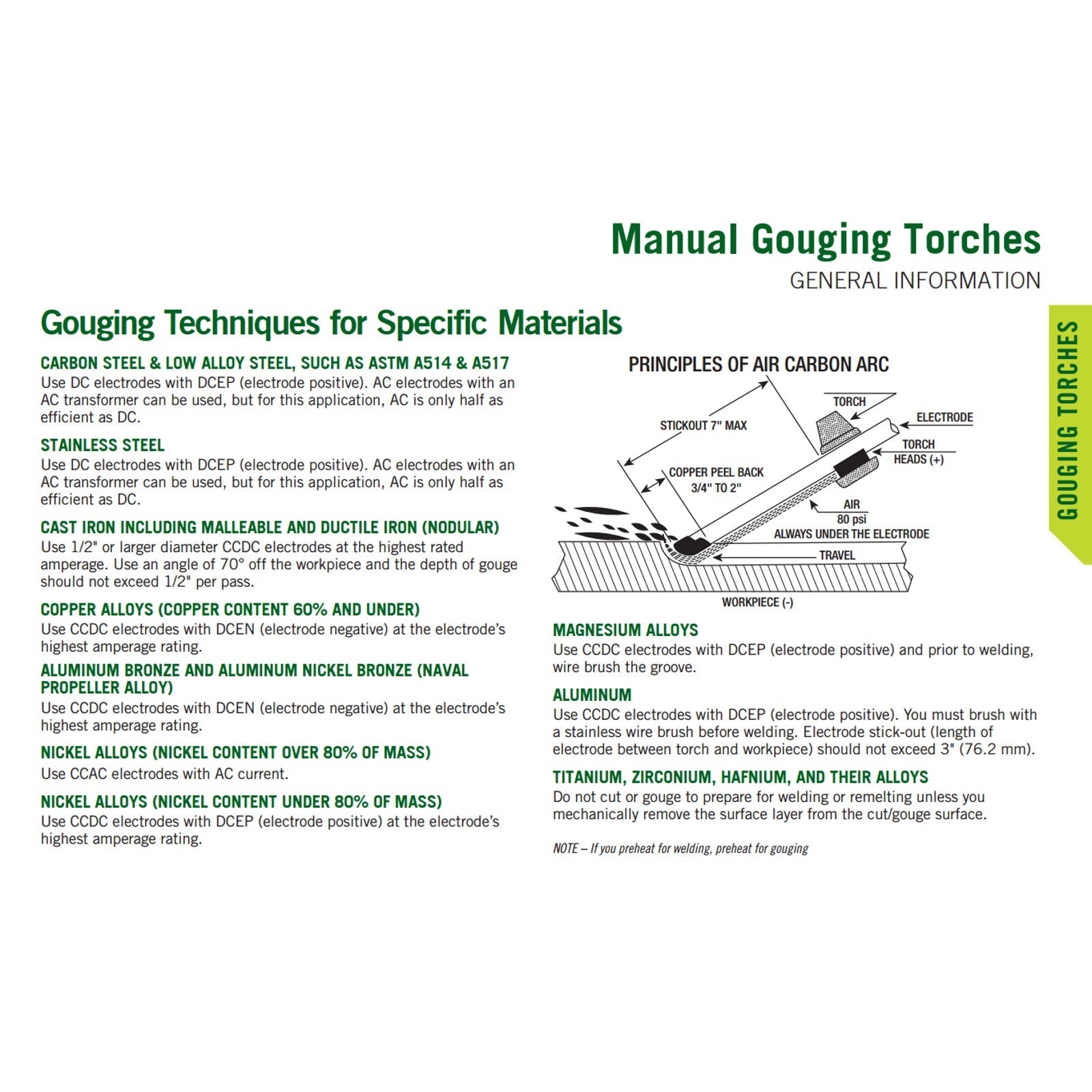

Air carbon-arc gouging (CAC-A) is the process of cutting/removing metal through intense heat generated from a carbon arc. Using a carbon electrode, compressed air and a welding power source (either a constant current, constant voltage, DC or AC), the arc created between the carbon electrode and the work piece melts the material, while the compressed air blows away the molten metal leaving a clean groove. The rate of metal removal is based on the efficiency of air stream in removing molten metal and the melting rate.

Only Angle-Arc® Torches work efficiently with the natural angles and movements of the arm and wrist.

Features

• Reliable torch design - market leader for over 60+ years

• Natural 15 degree torch angle - greater operator comfort

• Positive grip handle - greater operator feel and ease in positioning torch

• Durable front insulators - high impact and heat resistant, protects the torch metal parts

• Swivel cable - less cable twist and less strain on the operator

• Reduced weight - optimum cable and torch weight to minimize fatigue

• High quality cable hose - best quality cable hose offers high heat and abrasion resistance, non-conductive

• Power and air connection fully enclosed - protects the electrical connection from touching the work when in operation and eliminates the need to insulate with electrical tape

• Head assembly machined from copper alloy having four (4) air holes optimizing the air flow to the arc

• Lever spring rated at 225 lbs. per inch providing excellent clamping pressure on the air carbon-arc electrode

Uses

• Creating u-grooves for weld joint

• Removing old welds

• Gouging out cracks

• Cleaning and repairing castings

• Removing hard surface material

• Rough machining

Quick Specs

• Length: 10 Ft

• Amperage Capacity: Up to 1000 Amps

• Carbon Electrode Range: Pointed/Jointed - 5/32" to 1/2" | Flat - 3/8" x 5/32" | Flat - 5/8" x 3/16" | Half Round - 3/8" x 5/32"

• Air Requirement: 80 PSI | Flow Rate: 25 CFM

• Weight: 7.6 lbs

• 30 Day Warranty

Only Angle-Arc® Torches work efficiently with the natural angles and movements of the arm and wrist.

Features

• Reliable torch design - market leader for over 60+ years

• Natural 15 degree torch angle - greater operator comfort

• Positive grip handle - greater operator feel and ease in positioning torch

• Durable front insulators - high impact and heat resistant, protects the torch metal parts

• Swivel cable - less cable twist and less strain on the operator

• Reduced weight - optimum cable and torch weight to minimize fatigue

• High quality cable hose - best quality cable hose offers high heat and abrasion resistance, non-conductive

• Power and air connection fully enclosed - protects the electrical connection from touching the work when in operation and eliminates the need to insulate with electrical tape

• Head assembly machined from copper alloy having four (4) air holes optimizing the air flow to the arc

• Lever spring rated at 225 lbs. per inch providing excellent clamping pressure on the air carbon-arc electrode

Uses

• Creating u-grooves for weld joint

• Removing old welds

• Gouging out cracks

• Cleaning and repairing castings

• Removing hard surface material

• Rough machining

Quick Specs

• Length: 10 Ft

• Amperage Capacity: Up to 1000 Amps

• Carbon Electrode Range: Pointed/Jointed - 5/32" to 1/2" | Flat - 3/8" x 5/32" | Flat - 5/8" x 3/16" | Half Round - 3/8" x 5/32"

• Air Requirement: 80 PSI | Flow Rate: 25 CFM

• Weight: 7.6 lbs

• 30 Day Warranty

| MPN: | ARC61082009 |

|---|---|

| UPC: | 608246364636 |

Brands you trust at prices you can afford!

Over the past decade, we've become the country's most trusted one-stop online welding shop. We've done it with the guaranteed lowest prices, the best customer service in the industry, and a commitment to providing the best online shopping experience for all welders.

------------------------------

From The Blog

cutting

The Right Way to Start Your Plasma Cuts

“Plasma cutting” and “good plasma cutting” are two entirely different things. “Plasma cutting” is almost as simple as not pointing the nozzle at your face and pulling the trigger. But plasma cuttin...

TIG

The Ultimate Review of the Square Wave TIG 200

Flagships: Some people think they’re just cursed. The Titanic was the flagship meant to change how we traveled the seas. The Hindenberg was a flagship meant to change how we traveled the skies.

So ...

Projects

Sparking Inspiration: Spring Welding Projects To Brighten Your Space

As the flowers bloom and the weather warms up, it's the perfect time to get creative with your welding projects. Whether you're a seasoned welder or just starting out, there are plenty of exciting ...

Download Product Spec Sheet

Download Product Spec Sheet